Behind the Scenes: Shop Drawings

As anyone knows who has been through a complex construction project, thousands of decisions large and small must be made to bring a design vision to reality. From major decisions like style, size, material, and location to the infinite variety of fixtures, finishes, appliances, and colors, everything must be picked from the variety of options available. But what about custom components, things that must be designed rather than picked from a catalog? Many of these items are designed in great detail using a collaborative process between architects and fabricators using shop drawings.

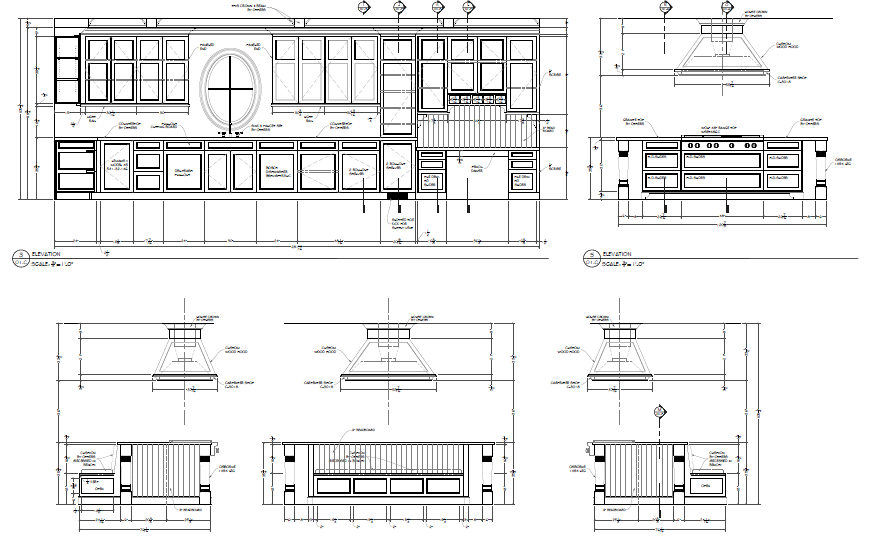

Generally, shop drawings are detailed working drawings that describe a building’s components to the high level of detail required for fabrication. Highly visible elements such as cabinetry are designed using shop drawings, but concealed systems such as structural steel, roof trusses, and heating and ventilation systems are designed the same way. The process progresses from general information to incredibly specific details, with input from many members of the design team coming together to reach a conclusion. Let’s take the example of a master bathroom design to examine how it works.

The architect works with the client to understand their requirements and desires: One vanity or two? How big is the shower? Platform tub or free-standing? Gradually, more detail is introduced: Do you want doors or drawers in the vanities? Are there cabinet towers above the countertop, or medicine chests built into the wall? Is there a separate makeup vanity built at a height to sit at? The answers to all these questions are synthesized into the architectural plans and interior elevations, which show the locations and sizes of all the components in the room, as well as their shape and character. Depending on the complexity of the design, the scale and budget of the project, and many other factors, these architectural drawings may be computer modeled or sketched by hand. But still more questions must be answered before the cabinet shop can begin building the vanity and trim components.

At this point, the architect will turn over the architectural drawings to a cabinet fabricator for further elaboration and development. The fabricator will use the architectural drawings as the basis for creating their own more detailed drawings: the shop drawings. These will usually be drawn at a larger scale than the architectural plans, which allows more detailed information to be included, covering both the appearance and the construction methods that will be used. Exactly how wide are the stiles and rails on the cabinet doors? What molding profiles are used in the different areas? Do drawers have dovetailed joints? Are the shelves adjustable or fixed?

When the shop drawings have been developed, they are submitted to the architect for review and approval. The architect examines the drawings to ensure, first, that the drawings match the design intent of the architectural plans. This could be verifying the sizes, the location of functions such as pull-out shelves or electrical outlets inside drawers, etc. Then the additional detail added to the shop drawings will be reviewed. Moldings, panels, alignments, and finishes are checked to ensure that the final product will turn out as intended.

After reviewing the drawings, the architect will return the drawings to the cabinet shop, with any requested changes marked on them. If necessary, this process of drawing, reviewing, and commenting can be repeated until the final drawings are approved for production.

The great benefit of the shop drawing process is that it allows each member of the design team to add their knowledge and expertise to the drawings. The architect doesn’t have to be an expert in every aspect of cabinet construction or truss design, because the designers who are experts in those topics add that information to the drawings. The cabinet maker or truss designer doesn’t have to understand the entire design project, because the architect will ensure the design matches the overall design intent. By allowing all the members of the design team to focus on their own areas of expertise and distributing the work of producing all of the information that’s required, the shop drawing process helps to bring all the details and decisions of a large project to a stunning conclusion.

Written by Alan Cook, studio manager at PCA